Based on STMicroelectronics AEKD-TRUNKL1 electric tailgate solution

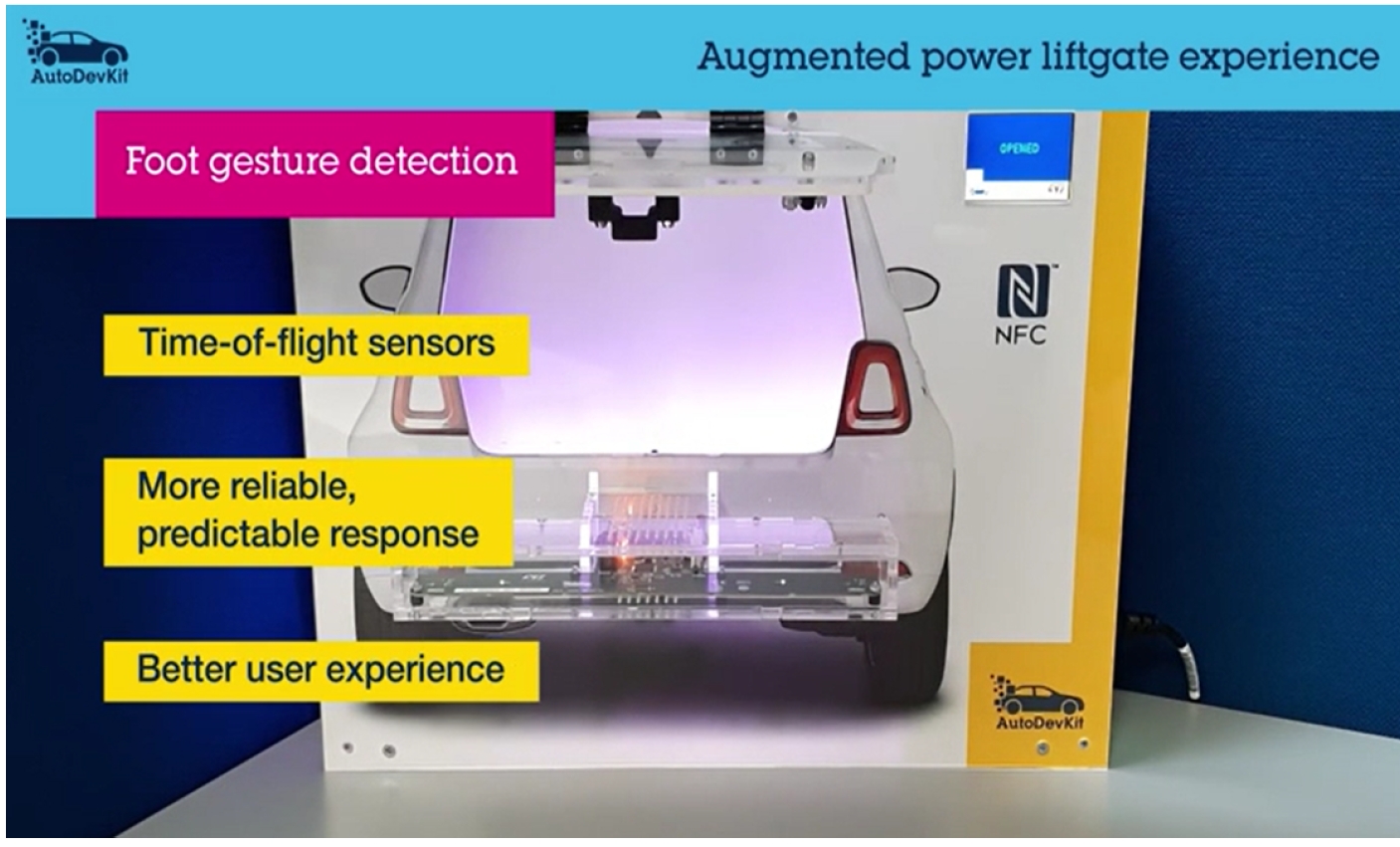

Electric tailgate systems installed in commercial vehicles require foot movement, which does not always result in successful opening of the rear trunk. This limitation is due to the type of sensor used, its location under the car's bumper, and the "kicking" posture required. Additionally, the sensors used do not allow for a redundant system (not including an internal fail-safe button) to open the trunk if it becomes inoperable due to being covered in mud or flooded.

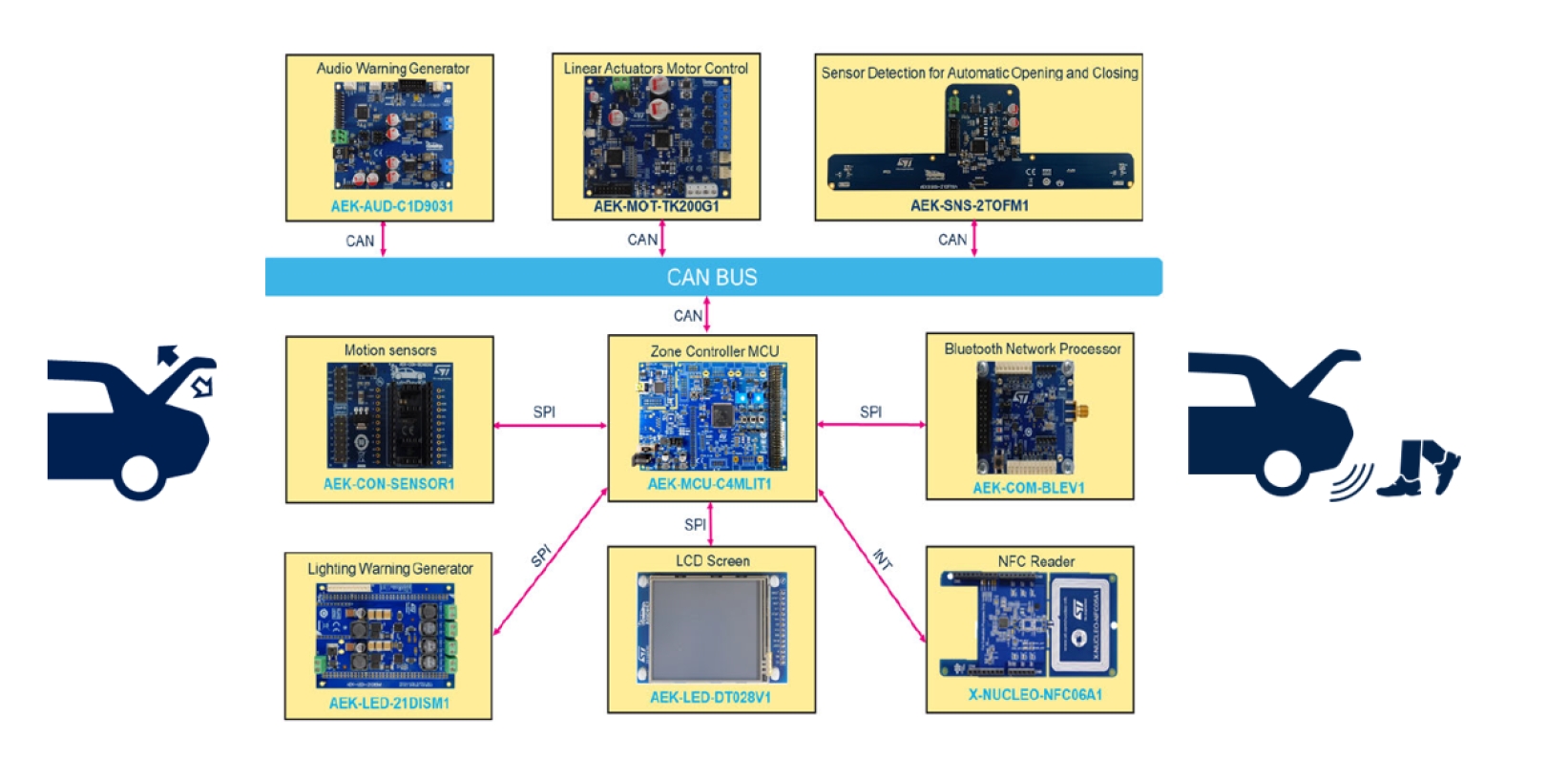

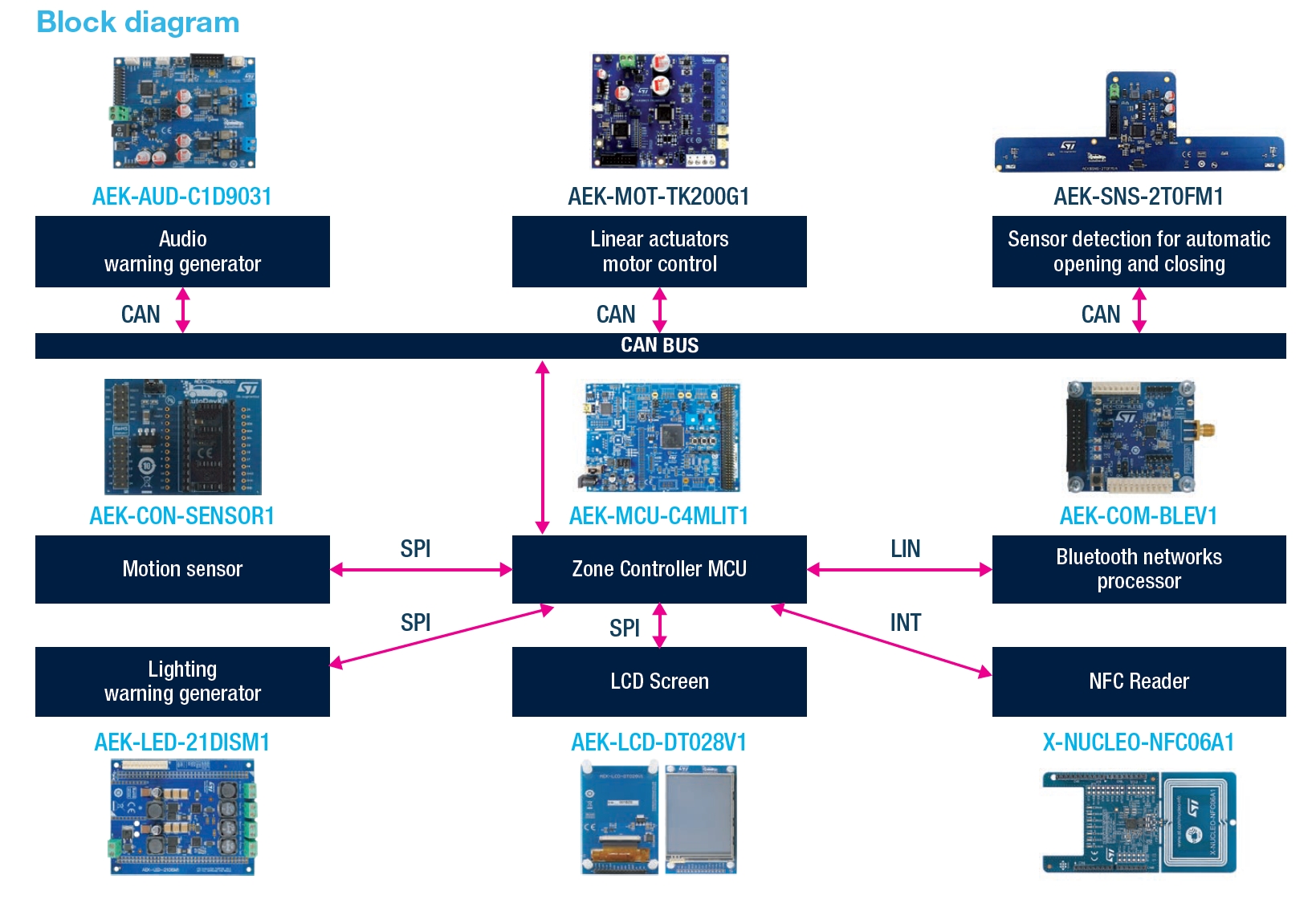

AEKD-TRUNKL1 solves all these problems while improving system security. Based on the latest example of a zone approach, the ST electric tailgate system controls seven subsystems in parallel: audible and visual alarms, NFC and Bluetooth® low-power communications, motion and foot detection sensors, and linear actuator control. LCD display and fail-safe push button controls are also available.

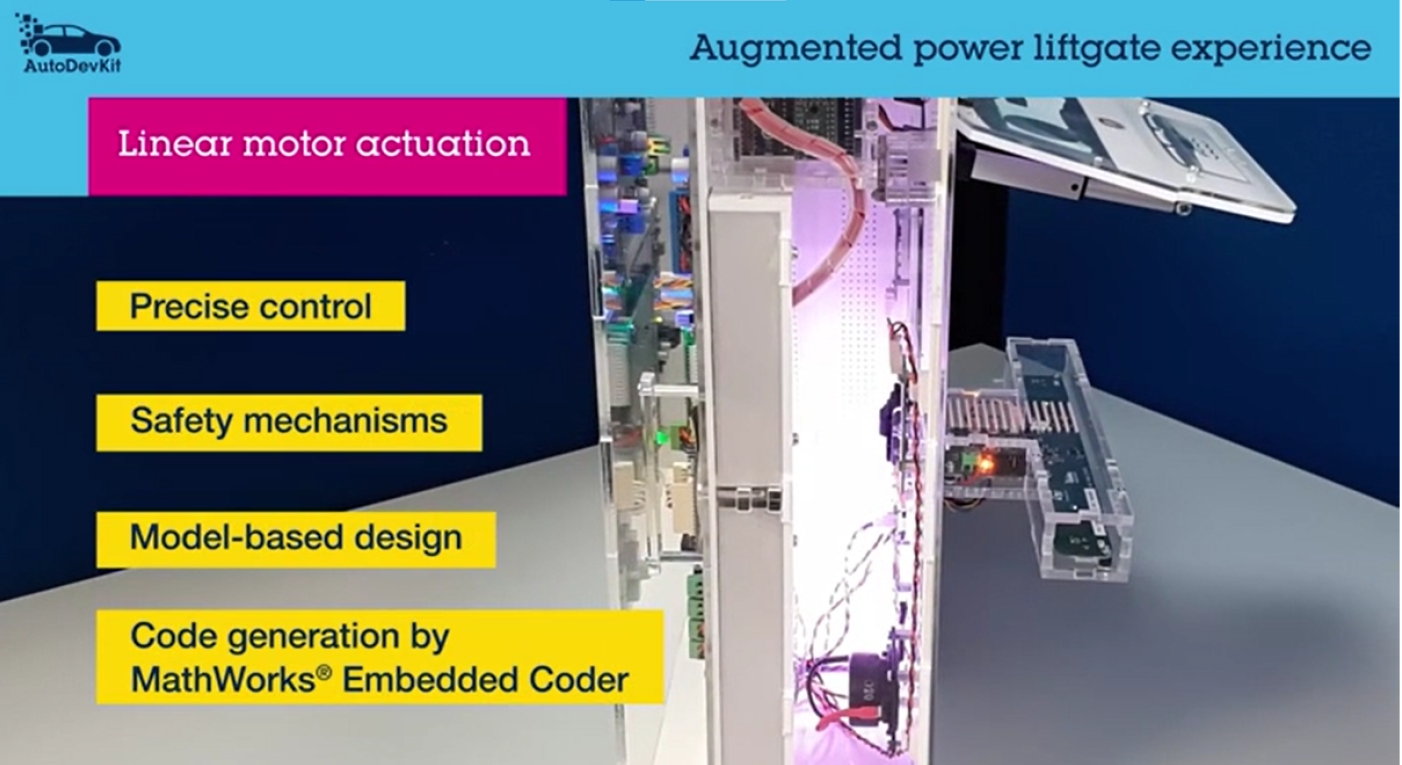

The first core function of the app is the precise control of the linear actuator that opens and closes the tailgate. Developed using model-based design. The code was generated using MathWorks Embedded Coder. Includes all control and safety mechanisms for drives based on dual feedback from Hall sensors and current sensing.

The second core function is the time-of-flight sensor under the bumper, which is used to identify specific foot movements, providing users with stable performance and avoiding unnecessary starts. Another huge advantage of time-of-flight sensors is the significant cost savings compared to commonly used sensors such as sonar.

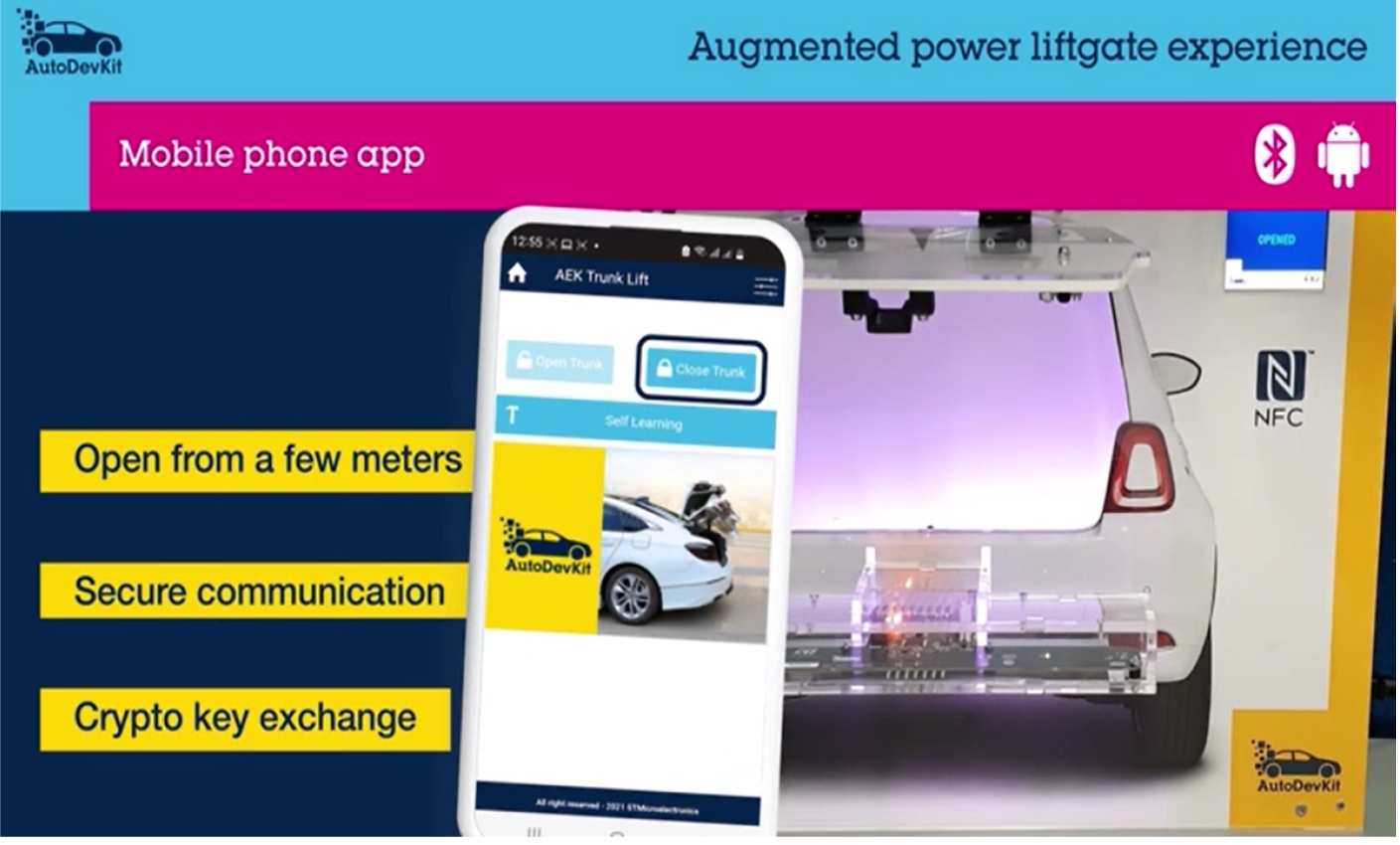

An NFC tag in a phone is an effective alternative to a sensor under the bumper, as a phone in a jacket pocket can be brought close to the NFC reader in the power tailgate system, even with hands full of bags.

A dedicated Android phone app controls the power tailgate system.

You can even open the tailgate from a few meters away and load luggage and packages. The app uses a token exchange with the electric tailgate system to ensure owner communication and identification. Additionally, the car owner's app can temporarily or permanently select another phone running the same app as a secondary phone with car trunk access.

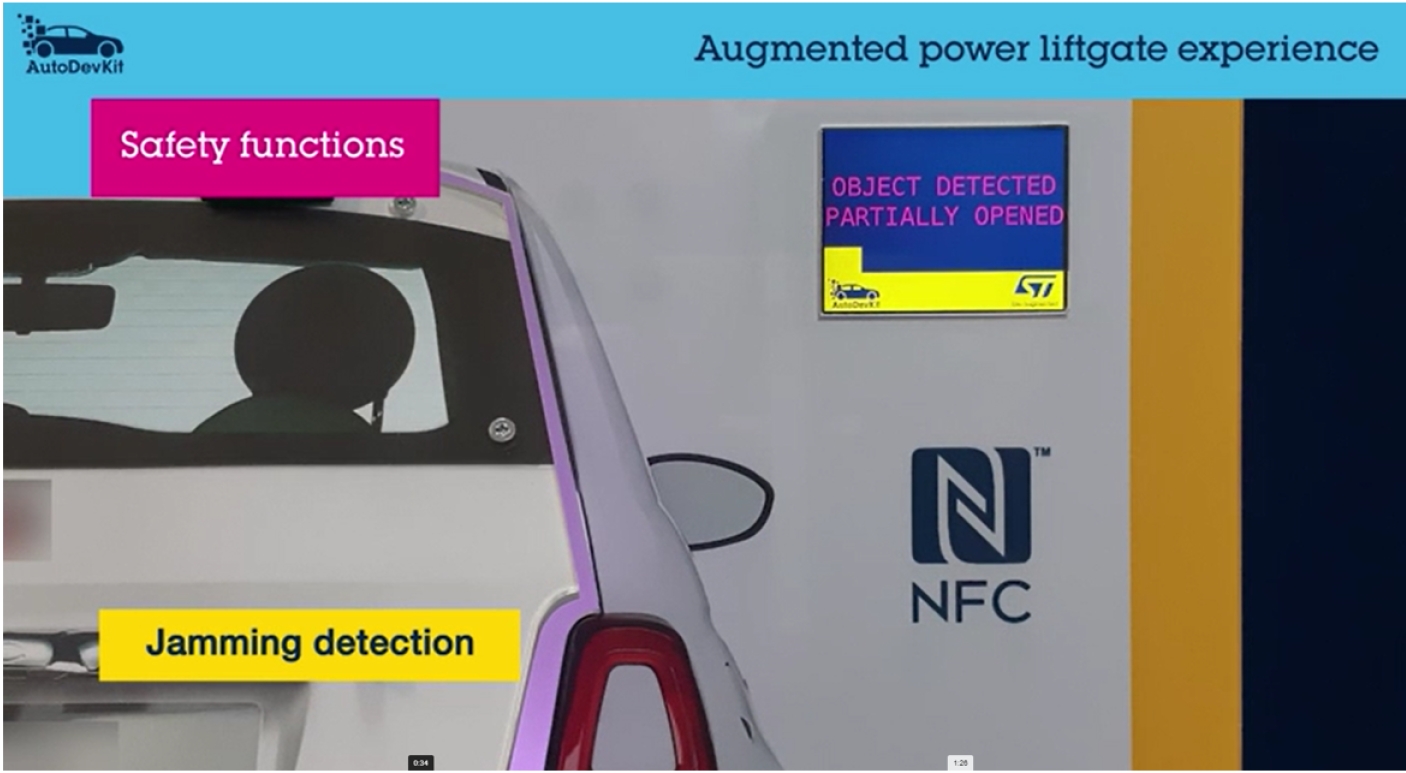

The motion safety subsystem is based on MEMS motion sensors, which can detect abnormal car movement during electric tailgate actuation when the engine is turned on and off, and suspend the action of the electric tailgate to ensure safety.

Audible and visual alarms are activated at the beginning of all tailgate activations and in the event of a safety issue (for example, the tailgate becomes jammed by an obstacle).

For demonstration purposes, an LCD display has been added to illustrate the different statuses and errors of the power tailgate system. There is also an external fail-safe button to open or close the luggage compartment.

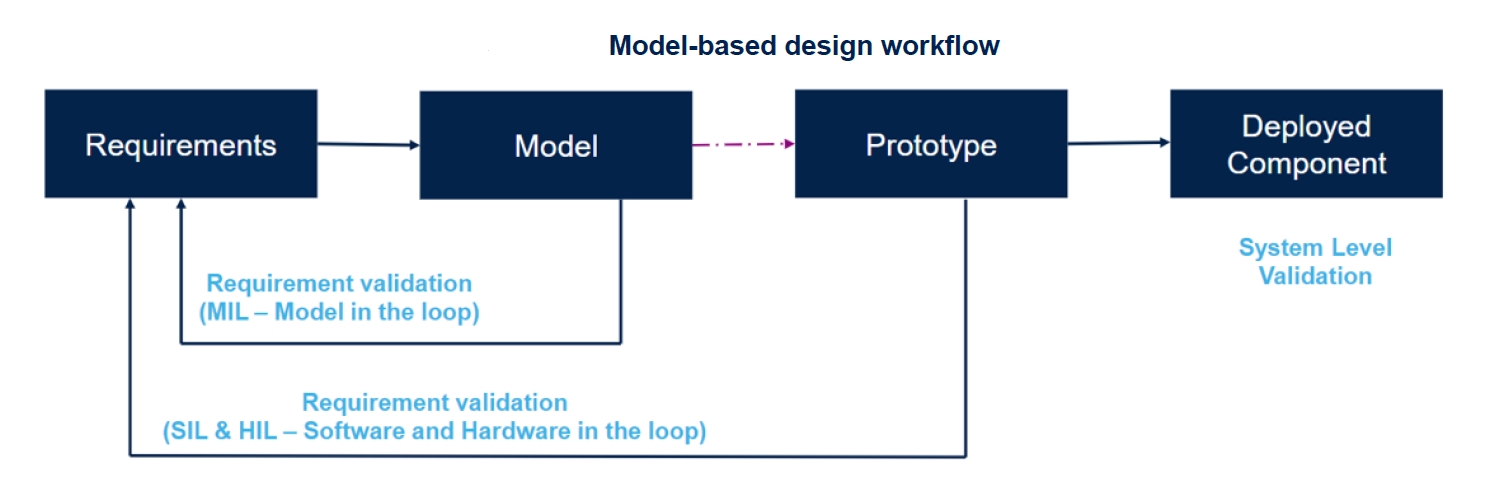

The main goal of model-based design is to ensure that the final product meets customer needs and requirements through a rigorous design and testing process.

You can perform development and testing tasks in parallel with system build throughout the process.

Defects discovered after a product is released can cost up to 10 times more than fixing defects discovered during the requirements phase. By applying a rigorous verification process at every stage of the development process, you can significantly reduce the cost of defect fixes.

Model design methods connect requirements, design, testing, documentation, and code using modeling methods.

Verification and validation at every stage of the design process ensures product quality.

Validation is performed using various simulation techniques: model in the loop (MIL), software in the loop (SIL), hardware in the loop (HIL) and rapid prototyping.

Automatic code generation is another major advantage of these models. It saves costs and development time, and improves overall product quality.

AEKD-TRUNKL1 is a fully assembled kit, consisting of ST function templates, allowing users to adjust functions. After development and testing is completed, it can be streamlined into one board based on the main parts used in each board to achieve the most practical mass production version!

Test report

https://www.st.com/resource/en/technical_note/tn1416-aekdtrunkl1-test-report-stmicroelectronics.pdf

Original factory related web pages

https://www.st.com/en/evaluation-tools/aekd-trunkl1.html

Development board documentation tools software, etc.:

https://www.st.com/en/evaluation-tools/aekd-trunkl1.html#tools-software

▶Scenario application diagram

▶Development version photos

▶Scheme diagram

▶Foot gesture detection

▶Linear motor control

▶Mobile APP control

▶Security control function

Core technology

• High reliability

• Can’t be opened accidentally

• Automatically stops if there are obstacles on the way to open the rear trunk

• Multifunctional solution including various subsystems

• Model-based design software

Project specifications

1. Control two linear DC motor actuators to open and close the luggage compartment

2. Motion detection to prevent accidental opening/closing of luggage

3. Rear luggage compartment locking and unlocking

4. Visual alert via flashing direction lights at the beginning of the luggage compartment opening/closing phase

5. Audible alarm via buzzer at the beginning of the luggage compartment opening/closing phase

6. Use NFC tag key to open/close the rear trunk

7. Open/close the rear luggage compartment via Bluetooth® low energy via the mobile app

8. Mini infotainment touch display showing luggage status

9.Self-calibration of system motor

10. Trunk opening/closing blockage detection

11. Rear trunk opening height adjustment